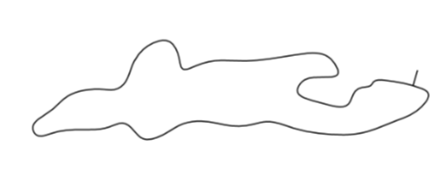

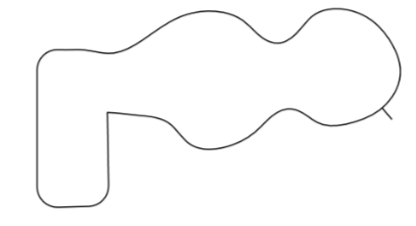

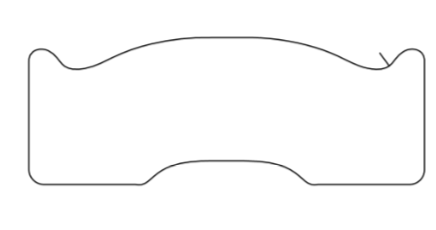

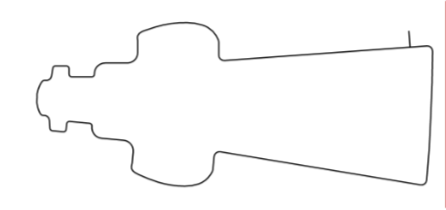

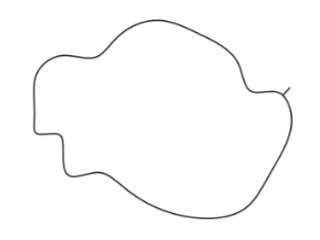

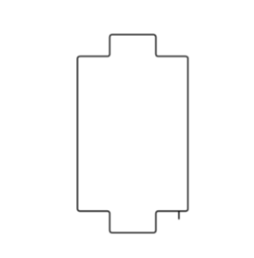

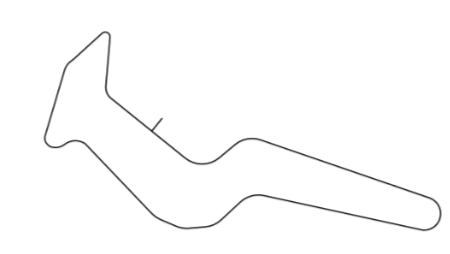

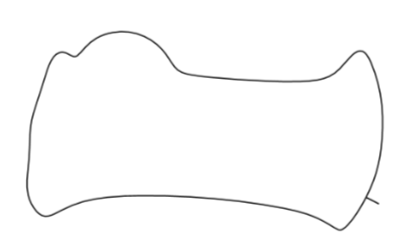

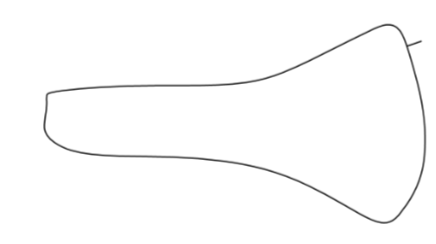

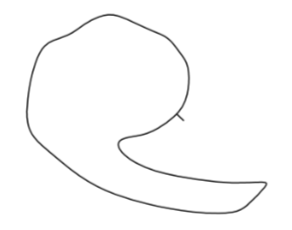

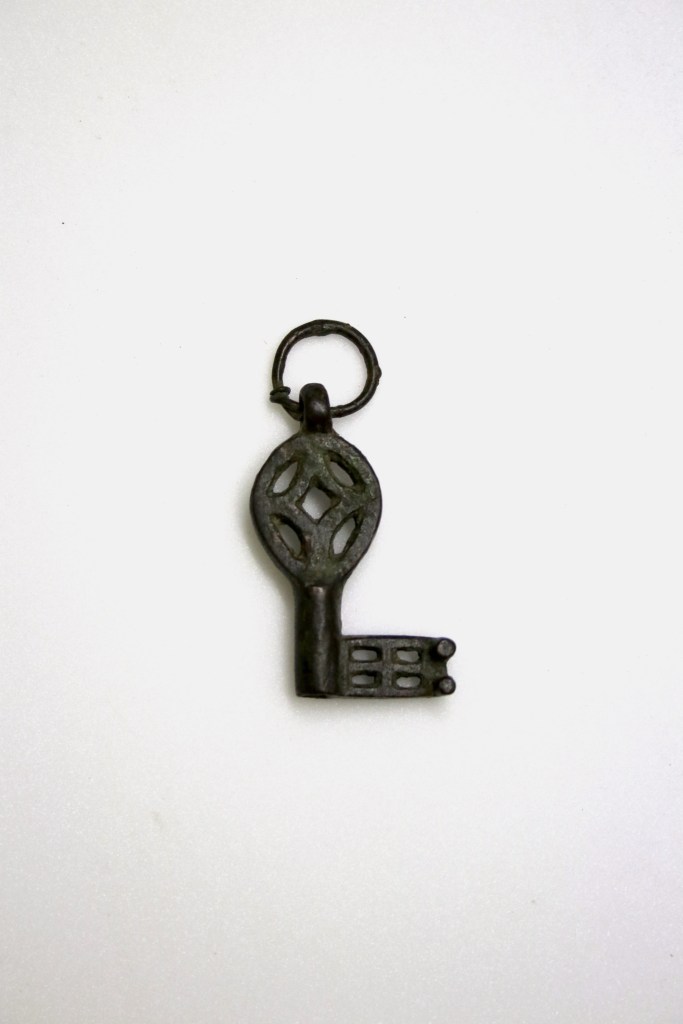

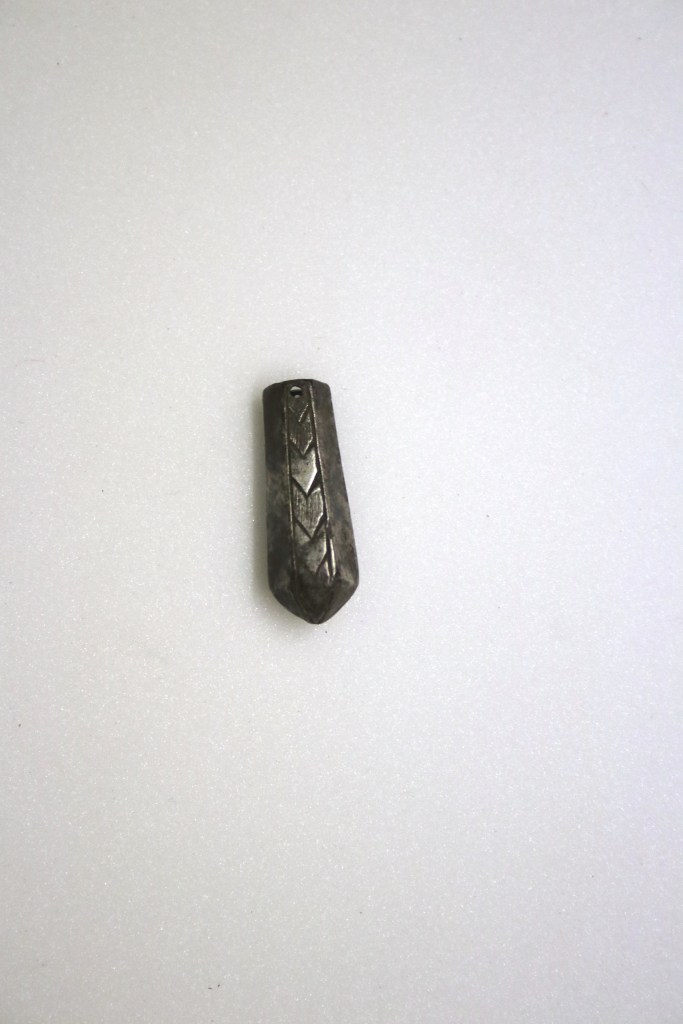

On the second day of my residency I have been starting to think about making moulds of the Steel shapes to allow me to cast them in wax. I will be be using the lost wax process to eventually cast Bronze sculptures.

I used alginate to make the moulds as it is more economical than silicone . However these moulds can only be used a few times. They are also a lot more fragile.

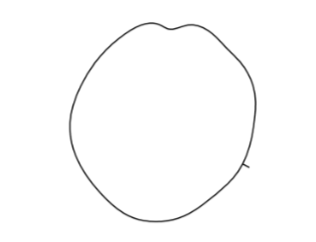

On a few of the first round of moulds I opened them too fast which distorted the surface of the mould. However I was really happy with the results! I really liked the surface detail this added to the shapes. I spent the rest of the day purposely distorting moulds to create surface texture…. a really happy accident!